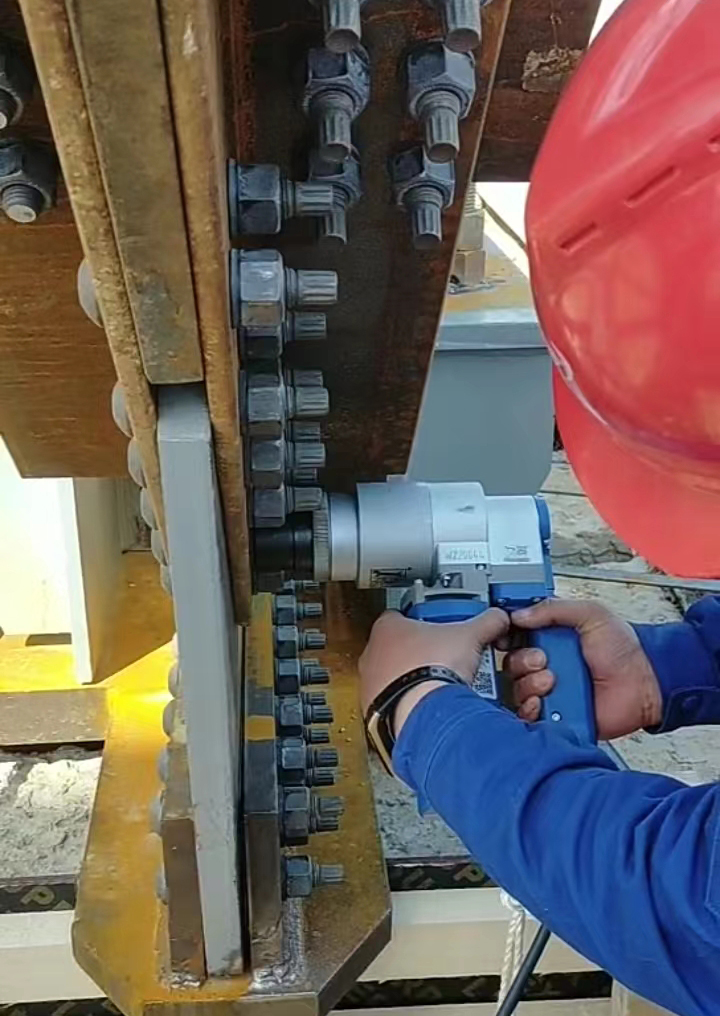

扭剪螺栓专用扳手主要是终紧扭剪型高强螺栓的,它的目的就是把扭剪型高强螺栓的梅花头打断即可。工作时将扳手头对准螺栓头,扣动开关即可开始工作,几秒后,螺栓梅花头将被扭断,然后抽出扳手扣动扳机将梅花头弹出,即结束工作。

The special wrench for torsion shear bolts is mainly used for final tightening of torsion shear high-strength bolts. Its purpose is to break the plum blossom head of the torsion shear high-strength bolt. When working, align the wrench head with the bolt head, press the switch to start working. After a few seconds, the bolt ring head will be twisted and broken. Then, pull out the wrench and pull the trigger to eject the ring head, which ends the work.

电动扭剪螺栓专用扳手特点

Characteristics of electric torque shear bolt special wrench

1、轻便灵活,使用方便;

1. Lightweight and flexible, easy to use;

2、扭剪速度快,可明显提高劳动效率;

2. The twisting and shearing speed is fast, which can significantly improve labor efficiency;

3、采用高强度钢,产品坚固耐用,不易破损;

3. Made of high-strength steel, the product is sturdy, durable, and not easily damaged;

4、通用性强,适合M16/M20/M22/M24螺栓

4. Strong versatility, suitable for M16/M20/M22/M24 bolts

扭剪螺栓专用扳手主要应用于钢结构安装行业,专门安装钢结构高强螺栓。高强螺栓可分为扭剪型和大六角型两种,国标扭剪型高强螺栓为M16、M20、M22、M24,非国标的扭剪型螺栓有M27、M30两种。一般的,对于扭剪型高强螺栓的紧固都要经过初紧和终紧两个步骤,而且每步都需要有严格的扭矩要求。在实践中,操作人员紧固扭剪型高强度螺栓时,一般是先采用冲击扳手或定扭矩扳手完成初紧,然后再利用扭剪螺栓专用扳手完成终紧。在实际操作环境下,钢架连接结构上需要使用多个螺栓,形成了螺栓集群,若将螺栓一个一个地按顺序一次性完成紧固,会产生无法均等紧固的问题,正确的操作方式为先将螺栓集群的每一个螺栓进行一次紧固,即初紧,当一次紧固完成时,所有的螺栓达到了基本相同的一次紧固扭矩,然后再将螺栓进行终紧固,直到扭剪型螺栓的颈部被剪断为止。现有的扭剪型77779193永利首页网址可分为初紧扭剪型77779193永利首页网址和终紧扭剪型77779193永利首页网址,它们通常都只有一种传动比输出。现有的初紧扭剪螺栓专用扳手的扭矩控制范围小,无法同时覆盖初紧和终紧高强度螺栓的扭矩需求,而现有的终紧扭剪型77779193永利首页网址,对扭矩不加控制,以扭剪断扭剪型高强度螺栓颈部为准,无法用于初紧高强度扭剪型螺栓。由此,对扭剪型高强度螺栓施工,需要一把初紧扭剪型扳手,通常可用冲击扳手或定扭矩扳手替代,还需要一把终紧扭剪型扳手,这样增加了用工成本,还增加了施工人员的搬运负担,特别是在高处作业时,携带两把电动工具非常不便。

The torque shear bolt special wrench is mainly used in the steel structure installation industry, specifically for installing high-strength bolts in steel structures. High strength bolts can be divided into two types: torsion shear type and large hexagonal type. The national standard torsion shear type high strength bolts are M16, M20, M22, and M24, while non national standard torsion shear type bolts are M27 and M30. Generally, the tightening of torsion shear high-strength bolts requires two steps: initial tightening and final tightening, and each step requires strict torque requirements. In practice, when tightening high-strength torsion shear bolts, operators usually first use an impact wrench or a fixed torque wrench to complete the initial tightening, and then use a special wrench for torsion shear bolts to complete the final tightening. In practical operating environments, multiple bolts are required on the steel frame connection structure to form a bolt cluster. If the bolts are tightened one by one in sequence, it will cause the problem of uneven tightening. The correct operating method is to first tighten each bolt in the bolt cluster, that is, initial tightening. When one tightening is completed, all bolts reach the basic same initial tightening torque, and then tighten the bolts finally until the neck of the shear type bolt is cut off. The existing torque type electric wrenches can be divided into initial tightening torque type electric wrenches and final tightening torque type electric wrenches, which usually only have one transmission ratio output. The torque control range of the existing torque control wrenches for initial tightening and final tightening high-strength bolts is small, and they cannot simultaneously cover the torque requirements of both initial and final tightening high-strength bolts. However, the existing electric wrenches for final tightening and torque cutting do not control the torque and are based on the neck of the high-strength bolt, which cannot be used for initial tightening and high-strength torque cutting bolts. Therefore, for the construction of high-strength torsion shear bolts, an initial tightening torsion shear wrench is required, which can usually be replaced by an impact wrench or a fixed torque wrench. In addition, a final tightening torsion shear wrench is required, which increases labor costs and also increases the transportation burden of construction personnel. Especially when working at heights, carrying two electric tools is very inconvenient.

本文由 扭剪螺栓专用扳手 友情奉献.更多有关的知识请点击 真诚的态度.为您提供为的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is dedicated by the dedicated wrench for torsion shear bolts. For more related knowledge, please click Sincere attitude. We will provide you with comprehensive service. We will gradually contribute more relevant knowledge to everyone. Stay tuned